Hybrid flex shock pad

The Hybrid Flex shockpad series for the E2 panel system is a more resilient olefin product than regular friable expanded polypropylene. It creates a durable, flexible shockpad that’s ideal for frequent installation/dismantling cycles and includes safety features that are similar to EPP.

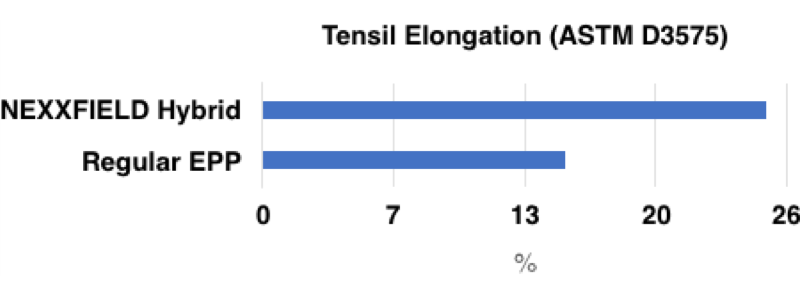

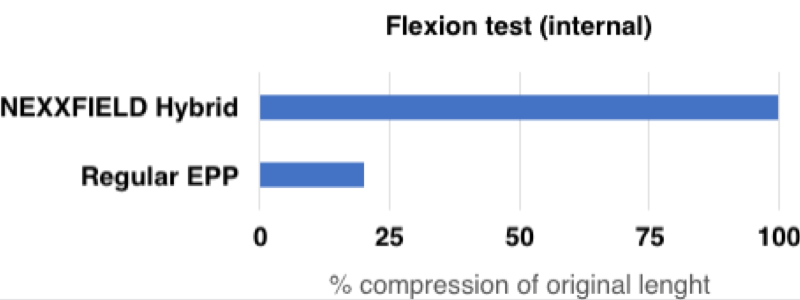

Some statistics

Following two years of rigorous testing, NEXXFIELD is proud to be the first in the field to create this unique shockpad system. The Hybrid Flex is less rigid that regular EPP systems, and creates a more flexible molded product with improved tensile elongation and tear strength while offering comparable shock absorption. It can also be molded using less energy (lower steam pressure = less energy) as compared to traditional EPP systems.

Advantages

Structural strength

The Hybrid Flex shockpad has a very high strength-to-weight ratio, with load-bearing structural support in a range of applications. It is capable of handling significant loads with little loss in form or shape.

Light weight

The Hybrid Flex shockpad is used in the automotive industry to improve safety and make components lighter, for example reducing system mass up to 10kg in seating systems.

Energy absorption

The Hybrid Flex shockpad is an excellent energy-absorbing material that can withstand multiple impacts without damage. Its light weight and exceptionally high strength-to-weight ratio make it a good choice for applications such as sports-field components.

Recyclable

The Hybrid Flex shockpad is an environmentally sound product, made from “green” material that is 100% recyclable. Manufacturing Hybrid Flex requires no VOCs (volatile organic compounds), chlorofluorocarbon, or other compounds that are recognized as damaging to the environment. The Hybrid Flex shockpad is also available in a recycled grade.